Alternative fuels will play a dominant role in the decarbonization of the marine and offshore sectors and are expected to yield the most benefits for reducing greenhouse gas (GHG) emissions. The current regulatory framework is focused on vessel emissions (tank-to-wake) rather than the overall life-cycle emissions of a given fuel (well-to-wake). However, it is recognized throughout the industry that the life-cycle carbon footprint of fuels provides the most complete description of their environmental impact.

This section presents comparative analyses of some of the alternative marine fuels and their life-cycle emissions, with the objective of offering a holistic view of the challenges associated with adopting low- and zero-carbon fuels.

LNG

LNG can be used as fuel in Diesel- and Otto-cycle engines, which differ in the amount of methane slip. The contribution of the emitted methane is accounted for using its 100-year GWP.

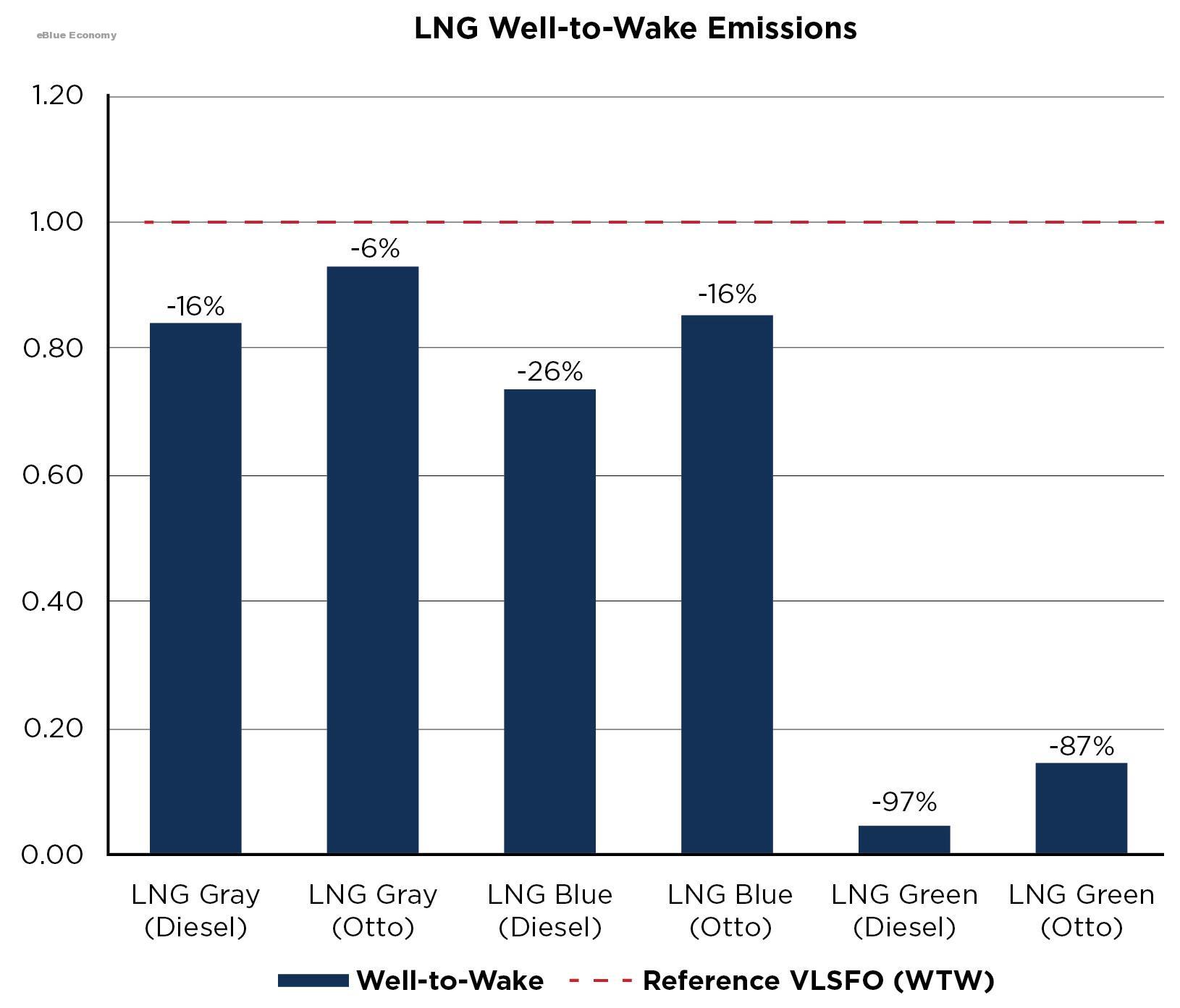

Since LNG is directly sourced from fossil reserves, an effective way to reduce its life-cycle carbon footprint is to employ CCS technology to the most energy-intensive processes during production, yielding blue LNG. Figure 6 shows a comparison of normalized well-to-wake emissions between gray and blue LNG when used in diesel and Otto-cycle engines. The values are normalized with the well-to-wake emissions of VLSFO for comparison.

It is assumed that the application of CCS can offer a 50 percent CO₂ reduction on the LNG production side, which reduces the life-cycle emissions by 26 percent compared to VLSFO in the Diesel-cycle case, and by 16 percent in the Otto-cycle case. These reductions can have a significant impact when assessed over the lifespan of a vessel, but they need to be weighed against the economic proposition of installing and operating CCS systems at fuel-production plants.

CO₂ can be removed either from the exhaust or flue gas of power generation systems or directly from the atmosphere; the latter is often referred to as “direct air capture”. Both technologies are based on the same fundamental principles but removing CO₂ from the exhaust or flue gas requires less energy because of its higher CO₂ concentration compared to air.

The separation of CO₂ from any stream requires two steps, capture and desorption/ regeneration. During capture, the CO₂ is absorbed into a solid or liquid by contacting the CO₂ source with the absorber. In the desorption/regeneration step, CO₂ is selectively desorbed from the absorber, resulting in a flow of pure CO₂ gas, and the original capture absorber is regenerated for further use. Over the last 20 years, many research groups have explored CCS technologies in order to increase the efficiency of the capture, as well as to reduce the volume and cost of the systems.

Although this comparison is drawn between gray and blue LNG, it is technically possible to produce green LNG in the form of e-methane or bio-methane, as Figure 6 shows, which has a dramatically lower life-cycle carbon footprint. However, the energy required for its production is very high and can only be economically attractive if the cost of renewable electricity used for production is low enough.

Based on the global average cost of renewable electricity from wind farms ($0.053/kWh), and electrolysis efficiency of 60 percent, and production cost of $4/kWh, the price of green LNG can be estimated at $1,782/ton, compared to the $240/ton for the gray LNG available at multiple ports worldwide. The ton price differential is enough to render green LNG less attractive than green ammonia, even without accounting for the tank-to-wake emissions benefit of ammonia. Considering the energy content, the difference could be marginal. Nevertheless, LNG is seen as an important transition fuel for the marine and offshore sectors, and it has been instrumental in the effort to develop knowledge, regulations, and safety protocols.

HYDROGEN

Similar to ammonia, the vast majority of hydrogen production is currently sourced from natural gas and coal. However, there are multiple initiatives around the world that aim to scale up the production of hydrogen from electrolysis using renewable energy.

Figure 8 offers a comparison of normalized well-to-wake emissions for gray, orange, blue, and green hydrogen, normalized against the well-to-wake emissions of VLSFO.

Gray hydrogen is estimated to have 64 percent higher well-to-tank carbon emissions than VLSFO, with a large fraction of that resulting from the high amounts of energy required for liquefaction and storage. However, applying CCS during production can result in a dramatic decrease of the well-to-wake emissions, to 74 percent lower than VLSFO.

Green hydrogen can achieve a 100 percent reduction in well-to-wake emissions and essentially offer a zero-carbon life cycle. Nevertheless, orange hydrogen (assuming a 50/50 blend of gray and green) can be used as a transitional fuel until the production of green hydrogen reaches the economies of scale that would make it commercially attractive. Current prices for green hydrogen can range from $2,000 to $6,000/ton, depending on the renewable electricity mix in its production