Redesigned Aft Layout Eliminates Oil Leakage and Enables Lower-Cost, In-Water Maintenance for the First Time

(ATHENS) ABS has granted Approval in Principle (AIP) to the Shanghai Merchant Ship Design and Research Institute (SDARI) for a revolutionary vessel design with a novel aft layout, which eliminates pollution and promotes efficient vessel operations.

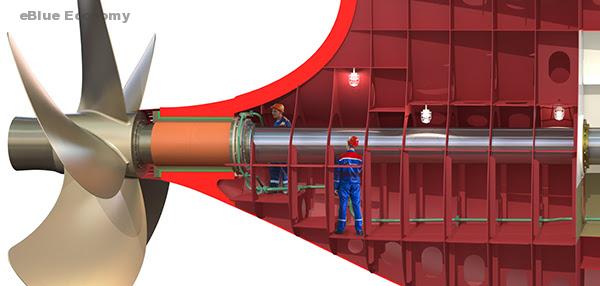

The SDARI design, developed in cooperation with Thordon Bearings Inc. and the National Technical University of Athens (NTUA), introduces a new approach to the vessel’s aft layout, including removal of the stern tube casting, employing seawater for lubrication, and creation of a chamber to permit in-water maintenance for the first time.

These innovations enable shipyards and owners to eliminate shaft-bearing oil leaks, simplify maintenance and lower costs.

Using seawater for lubrication of the stern tube bearing removes the risk of oil leakage. By enabling engineers and shipyard craftsmen to access the stern tube without the need for drydocking, the off-hire time incurred for bearing inspection and replacement will shrink from two weeks to one day while afloat.

The installation of an appropriate torsional vibration damper can also eliminate the Barred Speed Range, which is present in the vast majority of direct-drive diesel engine vessels.

Therefore, the new design can better support simplified compliance with environmental-focused regulations, such as the Energy Efficiency Existing Ship Index (EEXI), and can enable more efficient use of the engine’s propulsive power, since the whole RPM range of speeds is available for continuous operation.

It enables owners to easily consider an Engine Power Limitation (EPL) if required, to comply with Carbon Intensity Indicator (CII) power output requirements.

The resulting design proposal complies with all ABS rules and regulations and the tail shaft survey can be maintained at the maximum 15-year interval if the ABS TCM-W Notation is adopted.

“The concept of using seawater as a lubricant is well-established and the proposed design takes this further by removing the stern tube casting, decreasing the shaft line length, reducing the engine room space, and increasing the cargo space.

The elimination of the Barred Speed Range and the creation of an aft chamber to enable in-water inspection, enable significant efficiencies and cost savings for operators,” said Dr. Chris Leontopoulos, Director of Global Ship Systems Center, ABS Athens.

“Besides the benefits for operators, the new concept also gives more possibilities and flexibility for designers to optimize the engine room arrangement. Consequently, for the shipbuilding, the initial cost including the construction materials and labor cost may be reduced accordingly. It will contribute a series of benefits to all parts involved in the vessel,” said Mr. Wang Gangyi, Chief Engineer, SDARI.

“Our technical discussions have led to a revolutionary propeller shaft bearing system design that offers easy monitoring and maintenance of bearing and seal condition without shaft withdrawal, lower operational expenses, and elimination of oil emissions forever,” said Anthony Hamilton, Technical Director, Thordon Bearings, Canada.

About ABS

ABS, a leading global provider of classification and technical advisory services to the marine and offshore industries, is committed to setting standards for safety and excellence in design and construction.

Focused on the safe and practical application of advanced technologies and digital solutions, ABS works with industry and clients to develop accurate and cost-effective compliance, optimized performance, and operational efficiency for marine and offshore assets.