One more order for the supply of FLEX Tunnels from Damen Marine Components (DMC)

Damen Marine Components (DMC) has received another order for the supply of FLEX Tunnels, complete rudder systems and Rotor Manoeuvring Systems (RMS), for two new pusher-barge combinations.

The client is Den Breejen Shipyard from Hardinxveld-Giessendam. This yard will build the pusher-barge combinations on behalf of Rhenus PartnerShip GmbH & Co. KG in Duisburg.

This is a rare collaboration with these being the first complete inland vessels to be built in the Netherlands in a long time.

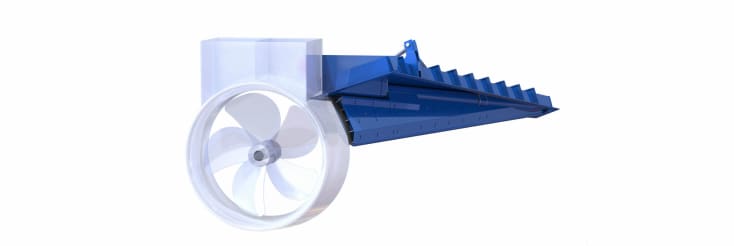

The FLEX Tunnels will be installed in the two newly built pusher-barge combinations. The highly-regarded retractable tunnel system significantly increases the efficiency and versatility of a ship. DMC is also supplying complete six-rudder systems.

Safer and more economical

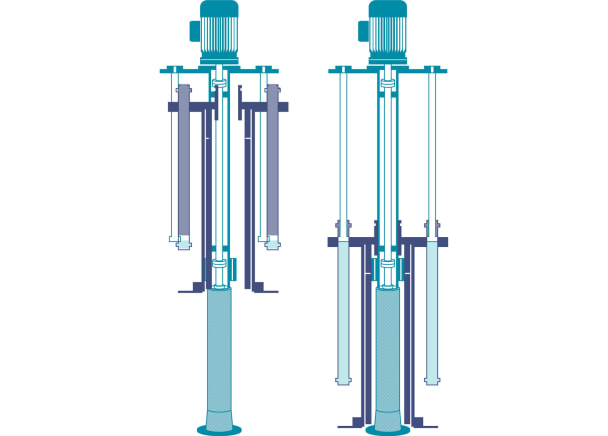

The bows of the barges will be fitted with Rotor Manoeuvring Systems (RMS). These systems, which have been supplied by Damen Marine Components since the late 1980s, guarantee the ship’s course stability, even in shallow waters and in strong crosswinds.

Inland shipping entrepreneurs’ interest in RMS has grown strongly in recent years, with more ships being designed for navigation at low water levels. RMS not only makes the vessels safer, it also provides significant savings in fuel consumption.

Full package

Den Breejen Shipyard has commissioned DMC to design, manufacture and install a complete package for two pusher-barge combinations.

In addition to the FLEX Tunnels and RMS with all associated hydraulics and controls, DMC is also supplying two Optima nozzles, two high-efficiency propellers, two drive systems to simultaneously synchronise six rudders (three for each rudder), plus a type SP2700 control system.

This is not the first time that DMC has equipped ships with FLEX Tunnels for Rhenus. The very first ship with FLEX Tunnels, the Rhenus Duisburg, was put into operation ten years ago and is still in operation without any problems.

For Den Breejen Shipyard, however, this order is their first project with Rhenus. Commercial Manager Ben de Rooy, says: “We’re an all-round shipyard, but we have never built a ship like this for Rhenus PartnerShip before, so we’re very happy with this collaboration.”

Short distance

Leo van Zon, Area Sales Manager at Damen Marine Components, comments: “We’re very happy with the confidence that both Den Breejen and Rhenus have placed in us. This is a special order for us.

The entire build will take place at a Dutch shipyard – a conscious choice by Rhenus. The major advantages of this are not only the short travel distances and communication lines, but also the perfect quality we can guarantee together.”

Innovations for sustainability

Herbert Berger, director of Rhenus PartnerShip, adds: “We no longer want to take small steps in the fields of sustainability and safety, but instead make ground-breaking progress.

That’s why we want to make use of all the innovations that are available for our new ships. DMC’s FLEX Tunnel and RMS are important systems to achieve efficient ship operations.”

The hull design was developed by maritime research centre DST (Development Centre for Ship Technology and Transport Systems) in Duisburg.

The first ship is expected to be commissioned by Rhenus in October 2023, with the second following in February 2024.

On the top image: FLEX Tunnel