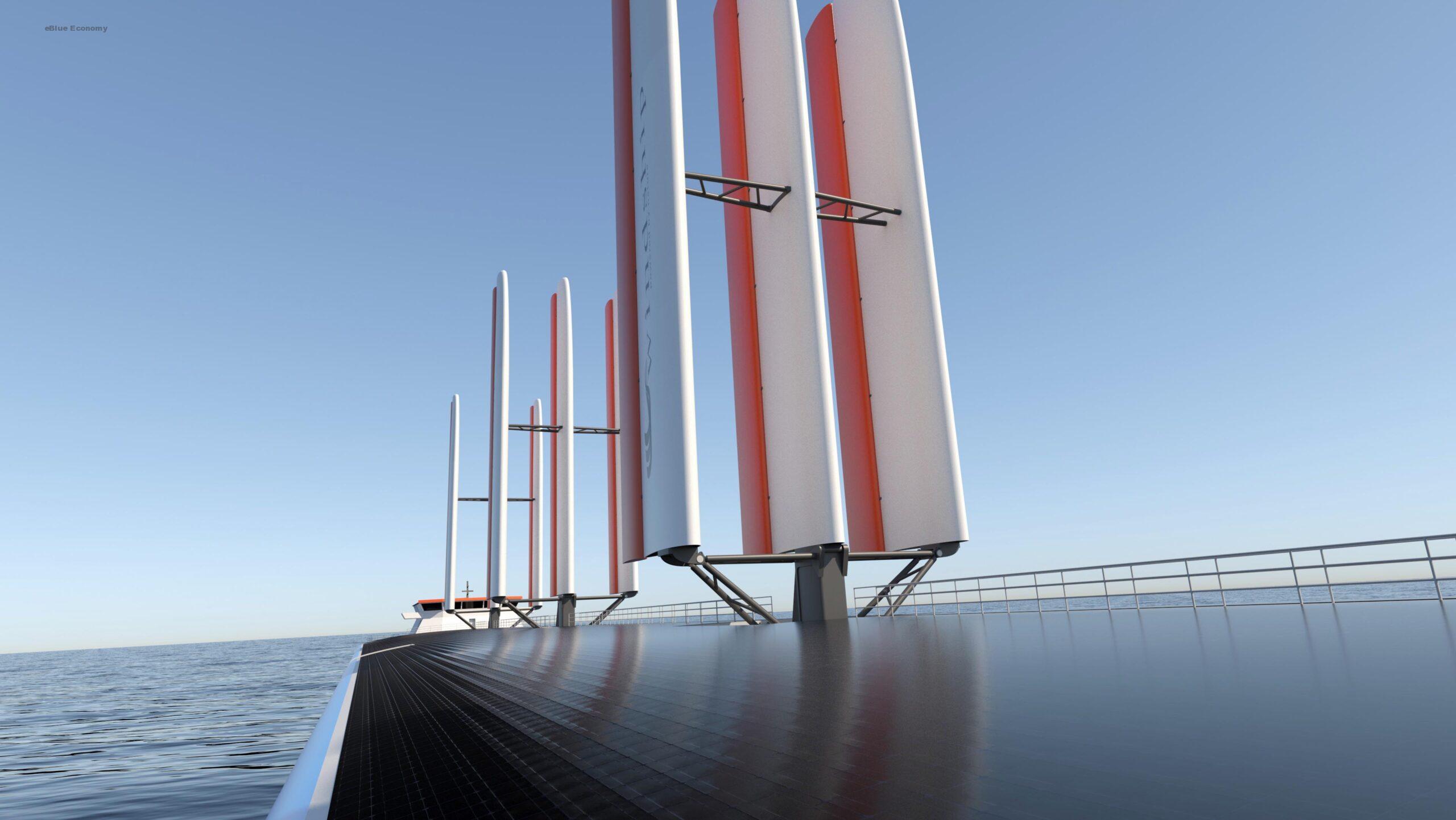

Windship Technology’s combination of wind power, efficient electric drive train, carbon capture, and optimization all work together to achieve a new Zero Emission concept.

Speaking about this significant development, Simon Rogers, Technical Director of Windship Technology stated: “Today everything changes. The world now has a True Zero Emission solution for the shipping industry with technologies that are available today and a commercial case rooted in economic sustainability. It’s a significant inflection point for the shipping industry. From a technical standpoint, Windship Technology is now verified.”

DNV’s analysis of Windship Technology’s True Zero Emission solution for shipping was extensive and thorough, based on a holistic approach factoring sound scientific practices and the data provided by Windship Technology.

Using the COSMOS analysis modeling suite for the drivetrain and based on the information provided, DNV assessed that Windship Technology’s solution captures 100% of the CO2 generated whilst providing 49% fuel savings.

Per Marius Berrefjord, Senior Vice President and Business Development Leader at DNV Maritime, said: “After extensive testing and modelling, the results from our analysis of Windship Technology’s innovative solution confirm that this design can provide a zero-emission system with the capability to save 49% of the expected fuel consumption of an Aframax Tanker.”

Brian Sweeney of Calix Limited, said: “Calix’s LEILAC Technology can produce very highly reactive lime with zero emissions. In our RECAST invention, this lime is used on a ship to absorb CO2, clean the exhaust gases and supplement power production. Given this independent verification of our modelling we are keen to engage in the planned demonstration programme. We look forward to working with Windship to deliver this shipping solution globally.”

Emeritus Professor Philip Wilson, Professor of Ship Dynamics at the Ship Science Department at the University of Southampton, said: “An incredible conclusion to a deep study by a leading registrar and classification society of ships. The system that delivers a true zero emission ship demonstrated by using real data is a remarkable and a humbling output to all the world ship operators, ship builders and ship designers. This has to be given a fanfare from the highest mountains and a wake-up call to the industry as a whole.”

In due course, Windship Technology will issue further information on its cost-efficiencies in relation to future fuels with evidence showing a comparative cost but with zero CO2 emissions, NOx, SOx, and particulate matters and VOC (volatile organic compounds) with a clean exhaust emitting non-toxic nitrogen, oxygen and water, further bolstering the economic case and providing solutions for commercial fleet operators, shipbuilders, and charterers.